How the Solar Cell Work?

With the spike in highway and municipal roads and a wide range of applications, spikes, and the quality of life has been more attention. In the actual application process, often because of installation problems and damage caused by spikes to reduce the phenomenon of life is to occur. Based on many years of construction experience summed up the spike problems often occur during the installation process:

The following is a spike common problems during installation:

1. Installed in the standard line. Marking is a resin material, is also attached to the ground, its own connection with the ground force is a certain limit. If the spike installed in the standard line, then the impact on power spike is completely passed on marking, so the impact of spike can easily be lost, but also the standard line has stuck out.

2. Spike installation location is not flat. This is a direct consequence resulting spike Shouli Bu uniform, the pressure spike is almost entirely on convex and concave parts. If you encounter a large tonnage of the vehicle, spikes are easy to break.

3. Spike installation location dirty. Spike spike depends on the firm level, glue and ground closely. If the installation position are dirty, the dust will absorb the glue during most of the adhesive force, resulting spike bonding is not strong, in face of external shocks, it is easy to fall off.

4. The amount of glue is not enough or excessive consumption. Amount is not enough, the firm will reduce the level of spike adhesive, reducing its service life; amount of excess, excess glue oozing from the spike to four weeks, it is easy to rub into the spike of the reflective film, the impact of the reflective brightness.

5. Glue applied unevenly. Installation spike, the glue only to the amount of moderate, but also spread evenly, so as to ensure that all parts are evenly spike, are there to avoid being crushed by Shouli Bu situation.

6. Epoxy glue when the ambient temperature is not enough to deploy. Two-component epoxy glue is glue, glue and curing agent mixture in accordance with a certain proportion, and can play by play even after the effect of mixing. However, due to cold weather in the winter epoxy glue condensation in a more powerful, not easy to stir, so we must first use the heating, let the glue to soften before use.

7. Insincere spike methods unscientific. Be sure to figure out just the right spike film that is not reflective on both sides, so as not to affect the glue stick on reflective film reflective film reflective brightness.

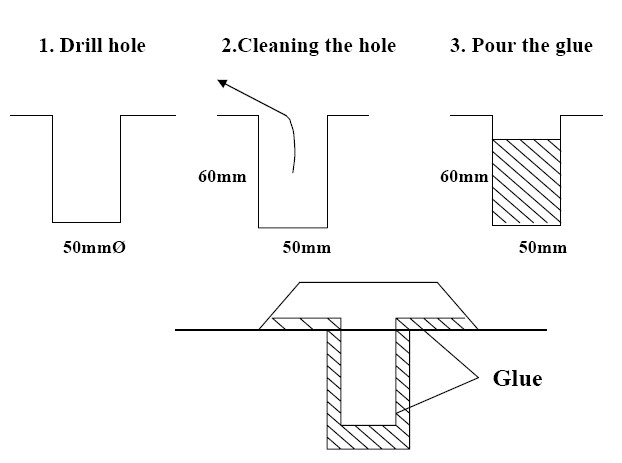

8. Spike mounting holes shallow holes fine. This is mainly for the cast aluminum with feet spike. Cast aluminum with feet spike because some depth to the ground and have a better impact resistance, compressive strength, longer service life. However, the installation process, if too shallow or too small holes, then the bottom spike and ground can not be given full access to the firmness of adhesion.

9. Glue curing time after installation is not enough. Spike installed, take some time to cure the glue to the spikes and connected to the ground closely, I recommend this time is 4 hours. However, the actual process, many people took less than two hours after installation to install isolation facilities to dismiss; In this case, if subject to impact and the vehicle rolled, spike light who will be deformed, in serious cases would fall off.

How to Install LED Solar road Stud?Continue to try and sum up their own set of methods, the following steps:

1. Placed in isolation facilities installation safety, and this is the weight of heavy, hope must not be ignored, but in the process of dynamic construction, whether new roads or road has been opened, everyone should be in a safe facility, If the opening of roads in the construction, installation of officers with the ratio of security personnel should be 1:1. Road construction is not open to traffic, the proportion of security personnel with the installation personnel should be 1:3.

2. To determine the installation location, ensure that the installation location of formation, on a scalable, cracks and uneven pavement, prior to finishing the road formation;

3. With the brush cleaned up the installation location, while ensuring that the installation location drying;

4. Take appropriate glue evenly on the spike;

5. The spike firmly pressed on the installation location, make sure the right direction, if the glue more, be sure to clean up;

6. If it is cast aluminum with feet spike, make sure the foot nail holes deeper than the depth of 1cm, nail pin hole diameter larger than 2mm;

7. Spike installation done within two hours after the first inspection, to ensure that all the spikes are not equipped with anti-, pressure mounted crooked or askew.

8. Other spike cured after 4 hours, removed installation of isolation facilities.

Spike installation is not a complicated matter, but there are many details that require attention. The details of the requirements for ensuring the quality and service life spike plays an important role.

Warning: file_get_contents(domain/mp3play.online.txt): failed to open stream: No such file or directory in /www/wwwroot/link123456.online/getlink/index.php on line 27

play youtube

play youtube

xvideos

porn

xnxx

sex việt

Phim sex

Nba Score Schedule

Aus Racing Results

Florida Atlantic Basketball Schedule

Longines Classic Horse Race

Que Tiempored New York Yankees Hat

Cso Criminal Search Bc

Farfetch Coupon Code

Paul Ratiff

Your Earlobes Are Thick And Chewy

Cheap Miami Vacation Packages All Inclusive

How To Ruin A Car Without Evidence

Pga Tour Winner Predictions

Connect Google Mini

Cbb Espn Scores

Bookings Com Uk

What Did Mr Harvey Do To Susie

Fc Barcelona News Now

No Ceilings 3

Filed under: How Solar Work?

Leave a Reply